CUSTOMIZED MANUFACTURING SYSTEM

The only one customized solution by the most appropriate ingredients among the d40 types of skin MBTI

Customized cosmetics manufacturing system

ENIMA™️

- Manufacturing system for customized cosmetics in the flexible mode

- Define a skin type as one of 40 different types of skin MBTI

- Manufactured customized cosmetics with fixed amount by loT system and robot

in sterilized environment by plasma in within 3 minutes and 50 seconds - 25,000 recipes per Items

- Freely changeable to bespoke recipes according to personal preferences.

Characteristics of customized cosmetic manufacturing system by ENIMA™

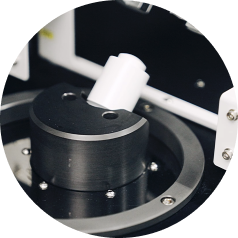

Dispensing process utilizing a robot

Simplified process with minimized pollution

Cap separation, ingredient supply, sub-ingredient connection, etc.

Quantitative dispensing and

instant manufacturing using an IoT system

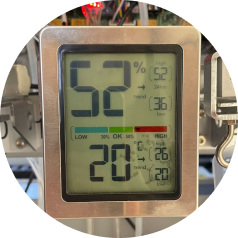

Hygienic environment maintained

through regular plasma sterilization, temperature/humidity system

disinfection, and constant

Air conditioner operates

"according to set temperature through automatic temperature control"

Planetary Mixer makes stirring of high-viscosity ingredients

possible in a short time

Customized cosmetic manufacturing system process by ENIMA™

System name

Custom cosmetic manufacturing system, ENIMA™

Cycle time

3 minutes 50 seconds

Size

1400 x 1400 x 1950 mm

Dispensed products

Lotion, essence, skin toner

Product weight

1,000kg

ingredients loaded in the machine

8 types of base (3 types of essence, 2 types of lotion, 3 types of toner) / 1 type of oil

/ 8 types of high potency ingredients

Viscosity available for dispensing

6,000 - 10,000cps

Daily production capacity

(8 hrs per day)

120 bottles (15ml)

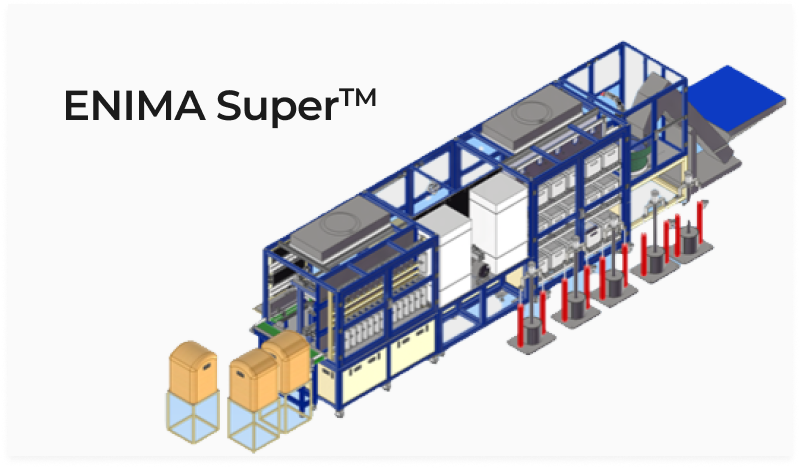

A factory system for manufacturing multiple items in a large scale and dispensing personally tailored cosmetics

ENIMA Super™️

- Mass production of high-viscosity products

- Possible to combine not only facial products,

but also hair care products based on personalized recipes - Monitoring of production line and automated order/ingredient management through automatic container transfer,

automatic label attachment and application of MES

Customized cosmetic manufacturing system process by ENIMA Super™

System name

Custom cosmetics manufacturing system, ENIMA Super

Cycle time

1~3 minutes

Size

1400 x 5000 x 1890 mm

Dispensed products

Facial / Hair care products

Viscosity available for dispensing

6,000 - 20,000cps

Production capacity

30ml, 100ml, 250ml

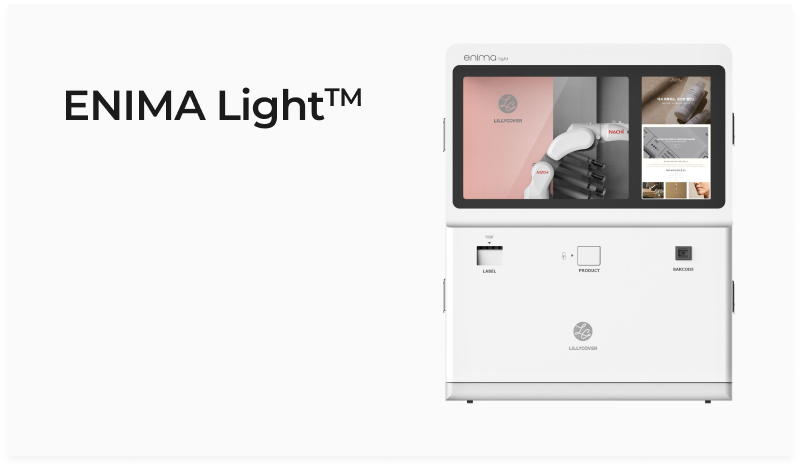

Compact customized cosmetics manufacturing system

ENIMA Light™️

- Compact customized cosmetics manufacturing system without space limit

- The compact size makes it easy to install in domestic and overseas hospitals and beauty shops

- Possible to provide professional premium service by combining high-performance products according to skin concerns

- Plans for operation of a comprehensive platform for skin health through connection with remote medical care

System name

Custom cosmetics manufacturing system, ENIMA Light™

Cycle time

3 minutes 50 seconds

Size

1400 x 900 x 1790mm

Dispensed products

Lotion, essence, skin toner, booster ampoule

Product weight

Less than 800kg

ingredients loaded in machine

5 types of base / 1 type of oil / 8 types of active ingredients

Viscosity available for dispensing

6,000 - 10,000cps

Daily production capacity

(8 hrs per day)

150 bottles(15ml, 30ml)