CUSTOMIZED MANUFACTURING SYSTEM

가장 적합한 성분으로 단 하나의 맞춤형 솔루션을 제공합니다.

맞춤형 화장품 조제 시스템

ENIMA™️

- 개인 맞춤 화장품 유연 생산설비

- 사용자에게 필요한 성분을 40가지 피부 MBTI 중 하나로 정의

- 주문과 동시에 로봇이 정량토출, 살균소독, 항온/항습 상태에서

약 3분 50초 내에 즉석 맞춤형 화장품을 정량적으로 생산 - 품목당 약 25,000가지의 레시피로 제조

- 개인의 취향에 따라 자유롭게 Bespoke 레시피로의 변경이 가능

ENIMA™️에 의한 맞춤형 화장품 조제 시스템 특징

로봇을 이용한 제조 프로세스

단순화 및 오염 최소화

*용기캡분리, 원료공급, Sub 원료 연결 등

IoT시스템을 통한

정량토출 및 즉석제조

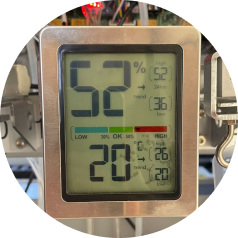

규칙적인 플라즈마 살균·소독

항온/항습 시스템을 통한

위생적인 환경 유지

설정한 온도에 맞춰 에어컨 작동,

자동 온도 조절

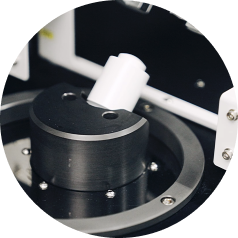

단시간 내 고점도 제품의

교반이 가능한 Planetary Mixer

ENIMA™에 의한 맞춤형 화장품 조제 시스템 프로세스

시스템명

맞춤형 화장품 조제 시스템, ENIMA™️

조제시간

(Cycle time)

약 3분 50초

사이즈

1400 * 1400 * 1950(mm)

제조 품목

로션, 에센스, 스킨 토너

중량

1,000kg

기기내 적재 원료

베이스 8종(에센스 3종, 로션2종, 토너 3종) /

오일 1종 / 효능원료 8종

토출가능점도

6,000 - 10,000cps

일별 생산 가능 수량

(일 8시간 기준)

120병(15ml)

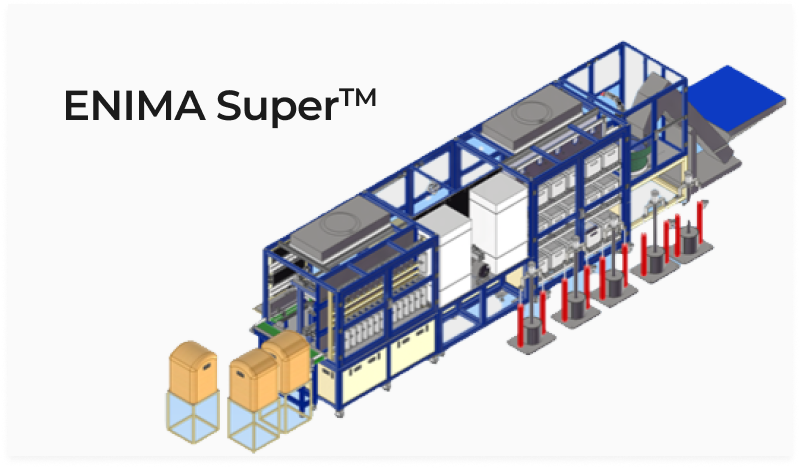

공장형 다품종 대량생산 및 맞춤형 화장품 조제 시스템

ENIMA Super™️

- 고점도의 제품 양산이 가능

- 개인화된 레시피를 바탕으로, 페이셜 제품 뿐만 아니라

헤어케어 제품의 접목이 가능 - 용기 자동 이송, 자동 라벨 부착 및 MES 적용으로

생산라인의 모니터링 및 발주/원료관리 자동화 실현

ENIMA Super™에 의한 맞춤형 화장품 조제 시스템 프로세스

시스템명

맞춤형 화장품 조제 시스템, ENIMA Super™️

조제시간

(Cycle time)

약 1분 ~ 3분 이내

사이즈

1400 * 5000 * 1890(mm)

제조 품목

Facial / Hair care 제품

토출가능점도

6,000 - 20,000cps

생산가능 용량

30ml, 100ml, 250ml

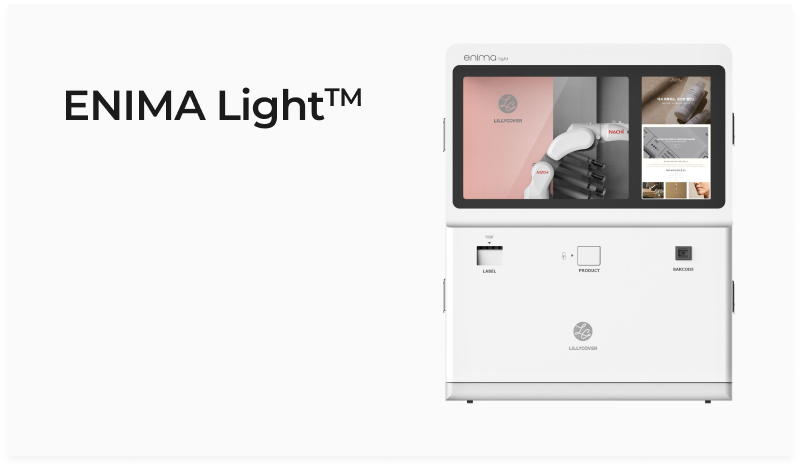

컴팩트형 맞춤형 화장품 조제 시스템

ENIMA Light™️

- 공간의 제약을 없앤 라이트한 타입의 맞춤형 화장품 자동화 장비

- 컴팩트한 사이즈의 설비로 국내외 전문병의원, 뷰티숍 설치에 용이

- 피부 고민에 따른 고효능 제품을 접목하여 전문적인 프리미엄 서비스 제공 가능

- 추후 원격 의료로 연결하여 피부 건강에 관련된 종합 플랫폼 운영 계획

시스템명

맞춤형 화장품 조제 시스템, ENIMA Light™️

조제시간

(Cycle time)

약 3분 50초

사이즈

1400 * 900 * 1790(mm)

제조 품목

로션, 에센스, 스킨 토너, 부스터앰플

중량

약 800kg

기기내 적재 원료

T.B.A

토출가능점도

6,000 - 10,000cps

일별 생산 가능 수량

(일 8시간 기준)

150병(15ml)